Bonus Read: Step-by-step Guide to Create a Mechanical Fiber Optic Splice Closure

Very often, people confuse fiber optic splice closure with a mechanical fiber splice. Though they may sound similar, they are two different things. If you would like to know more about fiber optic closure, check out our post on “All about fiber optic splice closure: How to select the right one?” If you’re interested in learning about mechanical fiber splices, continue reading.

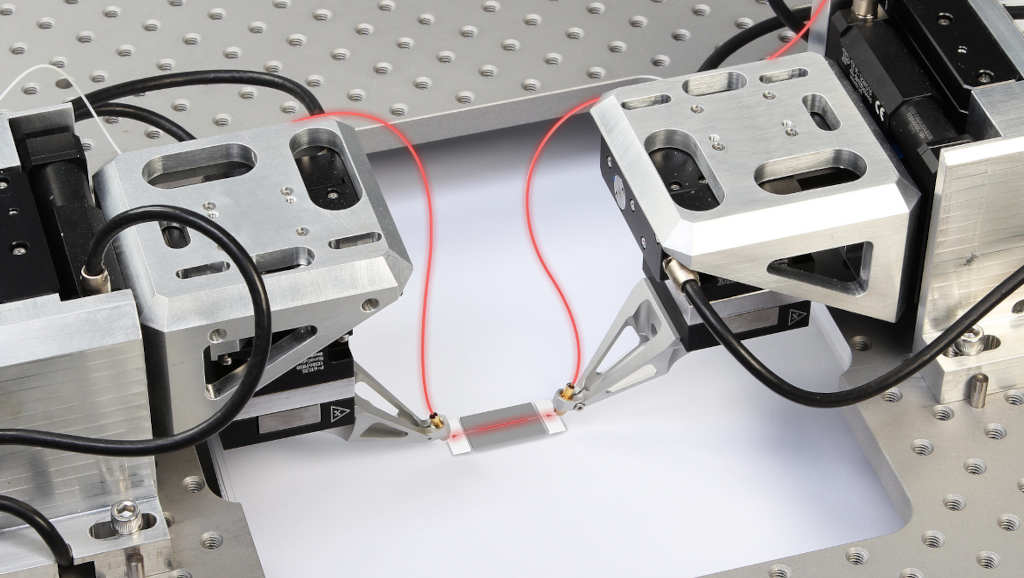

What is a Mechanical Fiber Splice?

Source: Toolboom

A fiber optic mechanical splice holds two fiber optic cables mechanically instead of welding them together. They look similar to fusion splice sleeves. Generally, the two spliced tips of the fiber cable are aligned mechanically using a special housing and index matching gel. The gel has a similar refractive index like the cable, thereby minimizing the air gaps. It helps the light signal travel from one cable to another with minimal reflection and loss.

Though mechanical fiber splicing helps in connecting fiber cables, it is still considered a temporary solution, as there are two separate cables. It is usually used to restore short-haul cables in fiber installations.

Though mechanical fiber splicing helps in connecting fiber cables, it is still considered a temporary solution, as there are two separate cables. It is usually used to restore short-haul cables in fiber installations.

Advantages of a Mechanical Splice

Here are a few reasons to choose mechanical fiber splices over fusion splices:

• They do not require any power supplies

• Mechanical splices are easy to do as they require minimal tools like a fiber cleaver and fiber stripper

• They are ideal for scenarios where fusion splicing is impossible or impractical

• They can be completed within a few minutes, making it the best choice for temporary connections

Disadvantages of a Mechanical Splice

Despite its numerous advantages, mechanical splices are not the best choice for all situations.

• It has a higher insertion loss. The insertion loss in a mechanical splice is significantly higher when compared to a fusion splice.

• They are not ideal for single mode fibers as it is extremely difficult for mechanical splices to align.

• They are more expensive than fusion splices. However, if you require only a couple of splices, then mechanical splices work cheaper as the cost of the machine for a fusion splice is high.

• The performance of a mechanical splice is dependent on temperature. They can be used only in environments that are not affected by temperature variations like inside an office building.

• They are not as reliable as fusion splices over a long period.

3 Types of Alignment Mechanisms of Mechanical Fiber Optic Splices

The working of a mechanical splice is simple. Two optical fibers are stripped from their sleeves and cleaned. They are then aligned and positioned exactly using mechanical clips or epoxy resin. The challenge here is to align the two fibers. There are three common alignment mechanism like:

• V-Groove Alignment

Source: Aniscom

It is the most commonly used alignment mechanism for aligning optical fibers. It has a base plate in which a V-groove is etched. Here are the steps in to follow:

• The cleaved fibers are placed in the groove and their ends are coupled together.

• An index matching gel bridges the gap between the two end to prevent air gaps and reduce reflection.

• The fibers are then held together using a locking mechanism. This lock also provides mechanical protection to the fibers.

• Epoxy resins can also be used in place of index matching gels. The resins help to keep the fiber in place.

• Bent-Tube Type Alignment

Source: Physikinstrumente

The bent tube alignment works just like a V-groove. Here a length of fiber is pushed into a curved tube. The natural springiness of the fiber optic cables makes it follow the curvature of the tube. The fiber gets positioned along the V-shaped wall of the tube. Index matching gels are used to hold the fiber in place.

• Precision Tube Type Alignment

In this type of alignment, two fibers are inserted from two ends of a tube. The fibers are aligned when they contact. The problem with this alignment is that it has higher insertion loss compared to other alignment types.

-

• The cleaved fibers are placed in the groove and their ends are coupled together.• An index matching gel bridges the gap between the two end to prevent air gaps and reduce reflection.• The fibers are then held together using a locking mechanism. This lock also provides mechanical protection to the fibers.• Epoxy resins can also be used in place of index matching gels. The resins help to keep the fiber in place.

Step-by-step Guide to Create a Mechanical Splice

Mechanical splicing is quite simple and requires only basic tools. Here is a step-by-step guide to walk you through the process.

Required Tools:

• Cleaver

• Fiber Optic Stripper

• Isopropyl Alcohol

Step 1: Strip the cables. Remove all protective sleeves and other coats, keeping the fiber cable naked. Clean the stripped cable using a clean cloth soaked in isopropyl alcohol.

Step 2: Cleave the fibers. Follow the instructions mentioned on the cleaver to split the cable.

Step 3: Place the cleaved ends of the fiber into the mechanical alignment device you are using. Use an index matching gel to minimize loss of the signal. Now, the light travels from one cable to another thanks to the index matching gel.

That’s it – you have completed the mechanical splicing. You can use a visual fault locator, a small device to check for signal loss in the mechanical splice.

Tips to Get Better Splices

• Use clean tools. Invisible particles like microscopic dust and dirt can cause damage to the optic fiber. So, clean all tools obsessively.

• Use a high-quality cleaver. Cleaving is the most important step of the entire process. So, make sure to use a high-quality cleaver that gives you an accurate finish.

About Adishwar Tele Networks

Adishwar Tele Networks is the leading supplier of fiber optic cable supplies and accessories in India. We offer a wide range of fiber optic accessories including fiber optic splice closure, mechanical and fusion splicing tools, cable blowers, duct rodders and more. Get in touch with our team to find the best fiber optic supplies at the best prices in India.